This article has been prepared and compiled by the content production unit of Ziggurat Industrial Group, the largest specialized authority on conveyors in Iran. In this article, we intend to comprehensively examine the conveyor and clear all the ambiguities in this field for you dear ones.

What is a conveyor?

Conveyor roller or conveyor roller is a cylinder that is used to facilitate the movement and movement of load on production lines. This simple chaining piece plays a vital role in streamlining the production process and saves time, money and manpower.

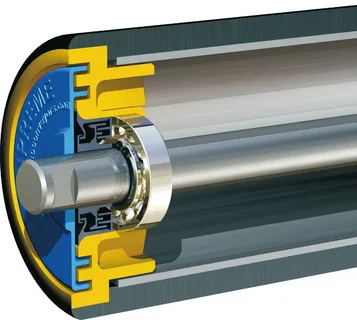

Conveyor roller is composed of various components such as shell, tube, bearing and coating. The type, diameter and length of the conveyor are determined according to the type of application and its load capacity.

Types of conveyors

Conveyors are produced in different types, each of which is suitable for a specific application. By knowing the types of conveyors, you can make an accurate and affordable choice. In the following, we introduce the most commonly used types of conveyors:

Steel conveyor: This type of conveyor has high strength and durability and is suitable for bearing heavy loads.

Steel conveyor: Steel conveyor is resistant to corrosion and moisture and is used for health and food industries.

Plastic conveyor: Plastic conveyor is light and suitable for production lines with low noise or light load.

Galvanized Conveyor: Galvanized conveyor offers a combination of steel strength and rust resistance.

Conveyor components

As mentioned, the conveyor is composed of various components. Knowing these components is effective in understanding the function and choosing the right conveyor:

Shell: The shell of the conveyor is a hollow cylinder made of steel, steel, plastic or galvanized.

Pipe: The conveyor pipe is made of steel and is placed inside the shell. The main task of the pipe is to bear the load and transfer it to the bearings.

Bearings: Bearings are components that allow the smooth rotation of the conveyor. The quality of the bearings has a significant impact on the lifetime and performance of the conveyor.

Coating: Conveyor coating can be made of different materials such as rubber, polyurethane or epoxy coatings. The type of coating is selected based on the type of load and the required amount of friction.

Conveyor applications

The conveyor has wide applications in various industries. Conveyors can be used wherever there is a need for smooth and safe movement of materials on production lines. Some of the main uses of conveyors are:

Assembly lines

Packaging lines

Food industry

pharmaceutical Industries

Automotive industry

Airports

warehouses

Choosing the right conveyor: a step-by-step guide

Choosing the right conveyor has a significant impact on the performance and lifespan of your production line. In this section, we introduce you to a step-by-step guide for choosing the right conveyor:

Determining the type of cargo: The first step is to identify the type of cargo you intend to transport on the conveyor. Pay attention to the weight, dimensions, shape and material of the load.

Load capacity calculation: Calculate the load capacity of the entire conveyor line according to the type of load and the number of conveyors per meter.

Choosing the type of roller: The type of conveyor must match the type of load and work environment. For example, use steel conveyors in wet environments and plastic conveyors for light load lines.

Choosing the diameter: The diameter of the conveyor affects its stability and strength. For heavier loads and higher speed lines, use a larger diameter conveyor.

Choosing the type of coating: The type of coating affects the amount of friction and protection of the load. The rubber coating is suitable for slippery surfaces and the polyurethane coating is suitable for high durability.

Conveyor maintenance and repair

Conveyor roller will have a longer lifespan with proper maintenance and repair. Some important points in conveyor maintenance and repair are:

Periodic lubrication: Periodically lubricate the conveyor bearings with suitable grease.

Periodic inspection: Check the conveyor regularly for wear, corrosion or any damage.

Timely replacement: If the bearings are damaged or the coating is excessively worn, replace the conveyor.

Cleaning: To prevent the accumulation of dust or spilled materials on the conveyor, periodically clean it.

Frequently asked questions about conveyors

In this section, we answer some frequently asked questions about roller conveyors:

Can the conveyor be produced with custom lengths? Yes, many conveyor manufacturing companies provide the possibility to produce custom lengths based on customer needs.

How much is the conveyor warranty? The warranty period of the conveyor varies according to the manufacturer and the quality of the raw materials.

Where can I buy a quality conveyor? To buy a high-quality conveyor, go to reputable and well-known companies in this field. Ziggurat Industrial Group, with a brilliant history in the field of production and supply of all kinds of conveyors, can guide you in this field.

Conclusion

Conveyor is a simple but vital part in production lines. By choosing the right conveyor and observing maintenance and repair tips, you can help streamline the production process, reduce costs, and increase the productivity of your business.

Ziggurat Industrial Group, as the largest specialized conveyor authority in Iran, hopes that this comprehensive article has been able to clear your doubts in this field. For more information about conveyor types, advice or placing an order, contact the experienced experts of Ziggurat Industrial Group.

Ziggurat Industrial Group is sincerely grateful for your cooperation until the end of this article.