This article, meticulously crafted by the content production unit of Ziggurat Industrial Group, delves into the world of roller bases, the often-overlooked workhorses that keep your rolling endeavors smooth and efficient. Whether you’re a seasoned roller in the industry or just starting out, understanding roller bases and their applications is crucial for maximizing productivity and streamlining your workflow.

What is a Roller Base?

A roller base is a platform equipped with rollers, typically made of steel or nylon, that facilitates the easy movement of heavy or bulky objects. They come in various sizes, weight capacities, and configurations to suit diverse needs. Imagine them as the invisible hands that tirelessly support your rolling tasks, ensuring effortless maneuvering and minimizing strain.

The Advantages of Utilizing Roller Bases

Integrating roller bases into your workflow offers a multitude of benefits:

- Effortless Movement: Imagine effortlessly gliding heavy materials across your workspace. Roller bases significantly reduce the friction between the object and the floor, allowing you to move substantial loads with minimal exertion. This translates to increased efficiency and reduced fatigue, especially when dealing with repetitive tasks.

- Enhanced Maneuverability: Tight spaces and awkward angles are no match for a roller base. The smooth-rolling action enables precise positioning and directional control, making it a breeze to navigate confined areas or maneuver objects into specific locations.

- Improved Ergonomics: By minimizing the physical effort required for movement, roller bases promote proper posture and reduce the risk of work-related injuries. This is particularly advantageous for frequent lifting or pushing heavy objects, helping to maintain a healthy work environment.

- Versatility Across Applications: The beauty of roller bases lies in their adaptability. They find application in a wide range of industries, from construction and manufacturing to warehousing and retail. Whether you’re transporting lumber, equipment, appliances, or even showcasing products in a showroom, a roller base can be your secret weapon for efficient material handling.

- Protection of Materials: The smooth rolling surface of roller bases safeguards your valuable materials from scratches, dents, or damage that might occur during transportation due to dragging or lifting. This is especially crucial for delicate items or finished products.

Choosing the Right Roller Base

With the plethora of roller bases available, selecting the perfect one for your needs requires careful consideration of several factors:

- Weight Capacity: The weight capacity of a roller base is paramount. Ensure it can comfortably handle the maximum weight of the objects you intend to move. Exceeding the weight limit can compromise stability and lead to safety hazards.

- Platform Size: The platform size should be appropriate for the dimensions of the objects you’ll be transporting. A base that’s too small might leave your materials precariously perched, while an overly large one could occupy unnecessary space.

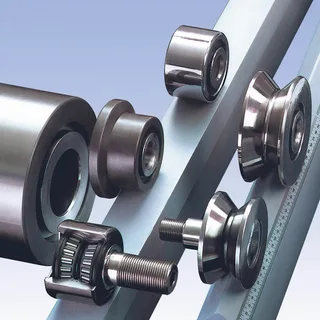

- Roller Material: Roller bases typically come with steel or nylon rollers. Steel rollers offer superior durability and weight capacity, making them ideal for heavy-duty applications. Nylon rollers, on the other hand, provide quieter operation and are gentler on delicate surfaces.

- Number of Rollers: The number of rollers on a roller base impacts stability and maneuverability. Generally, more rollers provide better weight distribution and easier rolling, particularly for heavier objects.

Maintaining Your Roller Base for Optimal Performance

Like any workhorse, proper maintenance is essential to ensure your roller base functions optimally. Here are some key tips:

- Regular Cleaning: Accumulated dirt and debris can impede the smooth rolling action. Regularly clean the rollers and platform using a mild detergent and a damp cloth.

- Lubrication: Periodically lubricate the rollers using a silicone-based lubricant to minimize friction and ensure smooth operation. This is especially important for roller bases used in dusty or dirty environments.

- Inspection: Conduct regular inspections to identify any signs of wear or damage on the rollers, frame, or mounting hardware. Replace worn-out components promptly to prevent safety hazards and maintain peak performance.

Beyond the Basics: Specialized Roller Bases

The world of roller bases extends beyond the standard platform with rollers. Here are some specialized types designed for specific applications:

- Turntable Roller Bases: These bases incorporate a rotating platform, enabling 360-degree maneuverability of objects. This is particularly useful for positioning large items or facilitating access from multiple angles.

- Tilting Roller Bases: Equipped with an adjustable platform, tilting roller bases allow for controlled inclines, making it easier to load or unload objects or facilitate drainage of liquids.

- Steering Roller Bases: These bases feature a single, steerable caster wheel, allowing for directional control while maintaining easy rolling. This is ideal for maneuvering objects in tight spaces or around obstacles.

Frequently Asked Questions (FAQs) About Roller Bases

Here are some of the most commonly asked questions regarding **roller bases**:

Can I use a roller base on uneven surfaces?

While **roller bases** excel on smooth, flat surfaces, some models can handle minor variations in terrain. However, it’s crucial to choose a base with larger diameter rollers for better stability on uneven ground. For significantly uneven surfaces, it’s best to opt for a different material handling solution like a pallet jack or forklift.

How much weight can a roller base hold?

The weight capacity of a roller base varies significantly depending on the model and construction. It’s essential to check the manufacturer’s specifications before using a base. Roller bases typically range from handling a few hundred pounds to several tons for heavy-duty applications.

What are some safety precautions to consider when using roller bases?

Safety is paramount when working with any material handling equipment. Here are some key precautions for using roller bases:

Never overload the base. Exceeding the weight capacity can lead to tipping, strain on the frame, and potential injury.

Ensure proper balance. Distribute the weight evenly on the platform to maintain stability during movement.

Use caution on inclines. Be mindful of the weight of the object and the angle of the incline when moving on a slope.

Wear appropriate footwear. Opt for closed-toe shoes with good traction to prevent slips or falls.

How do I maintain the brakes on a roller base with brakes?

Some roller bases come equipped with locking brakes to secure the object in place. Consult the manufacturer’s instructions for specific maintenance procedures for the brakes. Regular cleaning and lubrication are generally recommended to ensure their proper functioning.

Where can I buy a roller base?

Roller bases are readily available from a variety of industrial equipment suppliers and online retailers. Consider factors like weight capacity, platform size, and desired features when selecting a vendor. Ziggurat Industrial Group offers a wide range of roller bases to suit diverse needs – explore our website to find the perfect one for your application!

Do I need a permit to use a roller base?

In most cases, no permit is required for using a roller base. However, specific regulations might apply in certain workplaces or industries. It’s always advisable to check with your local authorities or safety officer for any applicable regulations.

Conclusion

Roller bases are unassuming yet powerful tools that can significantly enhance your workflow and improve material handling efficiency. By understanding their benefits, selecting the right type for your needs, and practicing proper maintenance, you can unlock the full potential of these versatile workhorses.

We hope this comprehensive guide from Ziggurat Industrial Group, the largest website about rolic, has equipped you with valuable knowledge about roller bases. For further information or assistance in choosing the ideal roller base** for your specific application, don’t hesitate to contact our team of experts. We at Ziggurat Industrial Group sincerely thank you for your support until the end of this article.