What is a Shaft and its Applications?

Understanding shafts is crucial in the industrial world. Today, the development of industries and their machines is on an upward trend. Machines need to be built powerful and with intelligent functionality. A shaft is a powerful metal rod made of steel that is responsible for transmitting power. The devices used in industry must be able to transmit power to each other. When two machines are connected, the shaft transmits power through a metal rod. The rotational motion of the shaft drives this function. Further on, we will explore complete information about the shaft.

Detailed Examination of a Shaft

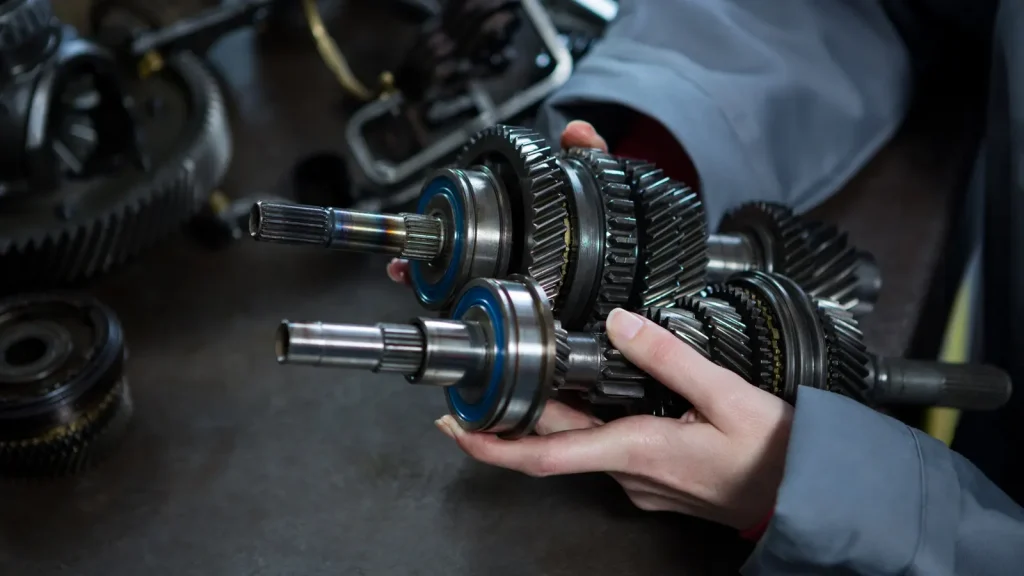

Understanding a shaft requires examining its details. Every device used is made of different components. The shaft is one of the main components in various industries. The transmission of torque from one device to another must be done by a steel piece, which is the shaft. In general, shafts are placed in axial tubes and are manufactured in various types; however, they are commonly used in a circular shape. The components of a shaft are:

Axis: The shaft body is the main and important component of this part. Rotary machines are the target devices of the shaft, as in these types of industrial machines, a steel device must establish the connection between the machines. The shaft axis is used to transmit power.

Gear: A gear is a part with a gear-shaped appearance that determines the direction of movement of the shaft. The gear meshes with the machine’s gears and transmits power in a specific direction. Understanding the shaft is possible with the help of its components and details.

Pulley or Belt Wheel: A belt is used to connect to the pulley of other machines. The belt is connected to the pulley of the machines and power is transmitted.

Joint: A joint is used to transmit torques at different angles.

Rotor or Bearing: The bearing is located in the axial tube and the presence of this part supports the shaft; it will also reduce friction.

Types of Shafts

Understanding shafts is very useful. Shafts come in various types and are used in different dimensions. If we want to categorize the shafts, we can mention transmission and machine shafts. We will examine the types of shafts below:

Hollow Shaft: Hollow shafts are lighter and can transmit more power. These hollow shafts increase design usability and create a space for design. The inertia of hollow shafts is less than that of solid shafts.

Solid Shafts: Solid shafts are one of the most commonly used types of shafts. They are used for repeated and daily use. Solid shafts are used in most household appliances.

Machine Shaft: Vehicles also have shafts. Understanding machine shafts is an integral part of machine part information. The crankshaft is one of the most consumed and used parts in a car that operates with the help of a shaft.

Axle Shaft: This type of shaft is used as a support and backer. The axle shaft is used fixed and for rotary support.

Spindle Shaft: This type of shaft is very short and has a small diameter. This type of shaft is used in the water valve spindle. There is a hole in the center of the spindle shaft. The larger the spindle, the larger the central hole will be.

Dwarf Shaft: The switch motor is coordinated with the dwarf shaft and they connect to each other. The different dimensions and shape of this product facilitate the connection to other axes.

Jack Shaft: Jack shafts are used to connect main moving machines to axle machines. This shaft is short and is considered an intermediate shaft.

Flexible Shaft: Flexible shafts are responsible for slow transfers and are used to change the angle of the flexible shaft.

What is a Shaft Made of?

Understanding the shaft requires accurate and integrated information. Shafts are made of various materials, with steel and steel alloys being the major constituents of the shaft; however, chromium and other alloys are used in some shafts. If the strength of the shaft is of high importance and we need resistant shafts, we can use chromium, vanadium, and chromium steel. We will examine the different types of shafts based on their material below:

Steel Shaft: As the name of the shaft suggests, the steel shaft is made of steel and carbon is the main material of this type of shaft. Of course, different materials such as aluminum, brass, etc. are also available on the market, which have different applications. Understanding the shaft and its constituents is important in the production of different industrial machines.

Hard Shaft: A layer of chromium is applied to hard shafts. This layer provides a great deal of protection against corrosion, wear, and decay. Ultimately, the shaft’s resistance will increase significantly.

Hard Chrome Shaft: This type of shaft is widely used and increases its resistance compared to the hard shaft, i.e. the highest resistance to corrosion and wear belongs to the hard chrome shaft type. The ck45 surface is covered