The guide role is responsible for guiding and guiding. It is very important to use this type of roller in production lines. Because a conveyor system needs many complementary parts. In general, the presence of this roller is necessary to establish order in the movement of the conveyor belt.

This equipment is used to guide and control the belt in its correct path along the conveyor belt, which is placed on its sides. In this way, the deviation of the belt is prevented and it will improve its movement. Of course, this movement requires a unique formula and design.

Introduction and application of the guide roll

A guide roller is used to control the operation of the belt in the straight path and the end section of the conveyor belt. This roller is located around the conveyor to control the speed and direction of the regular movement of the belt. The design of this device is done in a way to create positive results and improve the system.

Most of the conveyors that do not have a guide roller, cause the production system to stop, the sudden exit of the belt and dangerous accidents. This can also cause a lot of damage.

The use of guide rolls

Rollers, especially of the guide type, are a main element in the conveyor assembly. The function of their guide type is to control the movement of the conveyor belt. Their main use is to prevent the deviation of the transferred product on a conveyor belt. Due to the variety of production lines, they must be specially designed and built so that they can be used.

Since the guide rollers only have the task of guiding the tape and preventing its deviation, they do not bear much weight of the belt. It means that there is no need to make a guide roller with very high tolerance.

Where are the guide rolls placed?

The guide roller in the path of a conveyor belt is generally placed vertically and its task is to guide and prevent the deviation of its path. Of course, the installation location of this roller is also very important, because this issue can affect its performance. This roller should be placed in the upper part of the base of other rollers and on the sides. Because the guide roller must be able to create a wall at the edge of the conveyor belt. In this way, the transferred product does not fall, and the conveyor belt can go back and forth correctly.

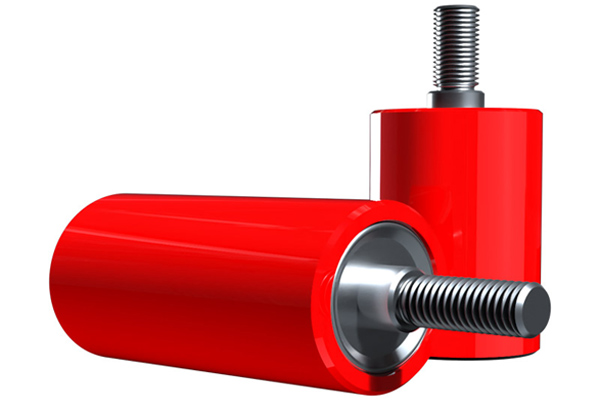

Of course, there are different types of guide rollers, but the most common type is small rollers that are placed in a standing position. This roller is connected to the base by means of a threaded shaft and a nut. On the other side of the upper roller, a cap is placed to protect the bearing.

Characteristics and technical specifications of a guide roll

This product has different types and each of them has specific features. Among these features, we can mention the material, the length and diameter of the shaft, and the type of bearing. Of course, the most important difference is in the type of roller and press or its replacement.

As mentioned, guide rollers are usually placed around transmission systems. Each set of conveyor belts needs different types of conveyor belts to move and transfer products on it. These belts are determined based on the material and each one has its own characteristics.

Weight and dimensions suitable for the transfer product

No need to bear weight

Appropriate transfer speed

Resistant to moisture and dust

Low erosion rate

Easy replacement

In most cases, a belt may deviate from its path after being installed on the machine chassis. This will cause a disruption in the work process. This is where the need for a guide is felt.

Guide roller structure and guide roller sealing arrangement

The structure of the guide roller is such that its outer part is in contact with the conveyor belt. This roller is made from steel, iron, aluminum, Teflon and plastic pipes. Inside its pulleys are anti-friction bearings and caps mounted on an axle. These yokes and bearings are lubricated using grease.

The end part and two ends of the roller shaft can be made in a threaded or square shape to connect to its base. Also, a cover is used to prevent dust, dirt and moisture from entering it. It is necessary to mention that the guide roller is not exposed to dust particles. Therefore, there is no need for a sealing test for that.

Guide roll components

The guide roller is responsible for gathering the conveyor belt and creating a wall on its edge. This makes the approximate shape of the semicircle of the conveyor belt cross-section complete. A guide roll consists of the following components:

Bearing body and housing made of steel

The shaft is made of different materials, especially metal

Bearings suitable for weight and speed

Rubber rims

Top material is metal, plastic or polyurethane

Application of guide roller in different industries

The main application of these rollers is in production lines, conveyor belts and production machinery. A guide roller helps the transfer product to reach the end of the belt with proper accuracy and speed. This will prevent future errors and problems.

The main application of the guide roller is in the following industries:

Metal production industries

Production of building materials

Mining

Paper and cardboard industries

Chemical production

Medical and food industries

Advantages of the guide roll

The rollers are random and are installed in the middle of the transmission axis. These equipments do not apply any force to the conveyor belt and will only make their movement smoother. Also, this roller holds the weight of the belt and the products on it. The most important advantages of the guide roller are:

High resistance to all types of pollution

Impossibility of penetration of moisture and dust into it

The possibility of repairing and replacing all parts

Ability to produce in all dimensions

Having a suitable design to prevent tape wear

Use of quality material

The possibility of production in high quantities

Cost effective production

Disadvantages of the guide roller

One of the observed defects of these parts is that its useful life is highly dependent on the component parts. When one of its parts fails, other parts of the roller will also fail. Also, replacing a part incurs an additional cost.

Another disadvantage of this roller is the bearings inside it. If the other parts are also healthy, the entire roller must be replaced with a new one. Also, the high temperature of the production lines can cause such equipment to be defective.

Guide roll price

To buy a conveyor belt guide roller, you must get complete information about its price and purchase conditions. In any case, the price of this roller depends on the type, dimensions, material, manufacturer, and the number you need. One of the factors affecting the price of this piece is its quality and standard level.

Of course, the level of supply and demand in the market can be effective in the final price of this roll. The price of this equipment is directly dependent on exchange rate fluctuations. In general, the price of such industrial products depends on various factors. You should first consider and check all aspects and then buy from a reliable source.

Guide roll function

The guide roller functions in such a way that it does its job by guiding and preventing the conveyor belt from slipping in the product transfer path. They will also benefit from this part to improve the performance and improve the useful life of the conveyor belt. These rollers are used in places of a conveyor belt system where there is a lot of tension on the conveyor belt.

By reducing the contact of a conveyor belt with the internal surface of the system, these rollers can reduce its erosion to a great extent. In addition, due to its rotatability, it also increases the useful life of other rollers in the conveyor belt system.

The most suitable function of this roller is in parts of the conveyor belt system that need guidance for a conveyor belt to pass through curves and changes of direction. Some of these sections will include bends in the conveyor, changes in height, changes in direction, and changes in direction.